Project Sherlock: An AI Module To Automation Models, Monitors and Optimizes Industrial Operations

Rockwell Automation has developed an artificial intelligence (AI) module that fits inside an industrial controller, “learns” the application that the controller is managing, and builds a model of it. It then monitors the operation continuously, looking for anomalies. If it spots a problem, it can trigger an alarm on an HMI screen or dashboard. Future versions will go beyond diagnostics to guide users on how to remedy the problem, or adjust system parameters automatically to fix the problem without human intervention.

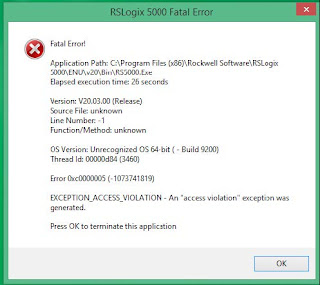

Creating diagnostic analytics solutions in industrial operations has long required expert data scientists with a deep understanding of the specific application to be analyzed. Those experts then require weeks, months or even years to understand and model the system. That expertise has been boxed in the new Project Sherlock artificial intelligence (AI) module unveiled by Rockwell Automation.

This data-driven analytics algorithm is delivered inside a module that fits directly into the controller chassis. Once installed, Project Sherlock AI leverages novel physics-based modeling to “learn” the application that controller manages. The solution scours controller tags to identify the application or allows users to choose what they would like modeled by selecting inputs and outputs via an add-on-instruction (AOI). Project Sherlock AI will then quickly learn from the stream of data passing through the controller to build a model. This process can be accomplished in a matter of minutes. Vast quantities of historical data are not required, nor must the data ever leave the automation layer.

The initial version of Project Sherlock AI will include ready-to-use templates for boiler, pump and chiller operations, ideal for process or hybrid applications. Users can model additional applications with guided configuration. Communications with the module are prioritized by the controller, so users can select how much data is sent and intervals of communication. The module does not add to controller CPU-load nor add to network traffic. Project Sherlock AI pilots have been running and producing results for the past 18 months. Customers will be able to purchase the module in mid-2018.

This new artificial intelligence engine is part of a larger, expanding ecosystem of analytics offerings from Rockwell Automation that run across the plant floor for devices, machines and systems, as well as throughout the enterprise. Rockwell Automation developers are building connections so users who employ FactoryTalk Analytics for Devices tools will be able to interface with Project Sherlock AI via the Shelby chatbot and action cards. Analytics from Project Sherlock AI will be easily integrated into the FactoryTalk Analytics Platform to integrate plant-floor data into business intelligence strategies.

Comments

Post a Comment